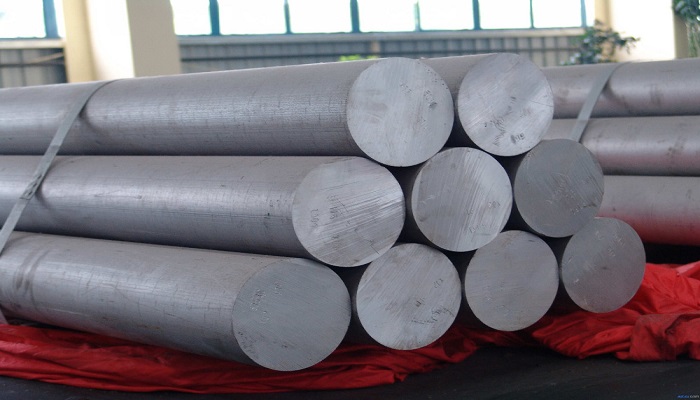

Nitronic Bars are austenitic, high-strength, corrosion-resistant products that provide higher-performance alternatives to many conventional 300 and 400 Series stainless steels.Nitronic Bars Available in ingot, billet, bar, wire, plate and master melt products, Nitronics® offer approximately twice the strength of 300 Series stainless steels.

Nitronic Bars provide excellent mechanical properties at both sub-zero and elevated temperatures, impact resistance at low temperatures and, superb resistance to high- temperature oxidation yet retain good weldability and fabricability, and remain non-magnetic even after extensive cold working.

We AOD refine, argon shroud, and bottom pour all Nitronic® ingots for optimum quality and yield. We ensure that we meet exact chemistry controls through use of the standard Nitronic® melting and processing practices. Our tight chemistry controls ensure continuing product consistency.

Nitronic Bars provides a combination of corrosion resistance and strength not found in any other commercial material available in its price range. This austenitic stainless has corrosion resistance greater than that provided by Types 316 and 316L, plus approximately twice the yield strength at room temperature. In addition, Armco Nitronic® Stainless has very good mechanical properties at both elevated and sub-zero temperatures. And, unlike many austenitic stainless steels, Nitronic® does not become magnetic when cold worked.

High Performance Alloys can make hot rolled, cold worked, strain hardened High Performance Stainless Steel (HPSS) bars in house. We have expanded to enhance product availability.

M.B.Metal Indiais the Leading Exporters & Suppliers of Nitronic 50 Round Bar. This Nitronic 50 Round Bar provides a combination of corrosion resistance and strength not found in any other commercial material available in its price range. This austenitic stainless steel has corrosion resistance greater than that provided by Types 316, 316L, 317 and 317L, plus approximately twice the yield strength at room temperatures. Unlike many austenitic stainless steels, Nitronic 50 does not become magnetic when cold worked or cooled to sub-zero temperatures.

Standard:

Fermonic 50 Round Bar

UNS S20910 Round Bar

Werkstoff 1.3964 Round Bar

DIN 1.3964 Round Bar

AMS 5861 Round Bar

Outstanding galling resistance at both ambient and elevated temperatures makes Nitronic 60 Round Bar a valuable material for valve sterns, seats and trim; fastening systems, including nuts and bolts; screening; chain-drive systems; pins, busings and roller bearings; and pump components such as wear rings and lobes. Nitronic 60 Round Bar provides a significantly lower cost way to fight wear and galling compared with cobalt-bearing and high nickel alloys. Its uniform corrosion resistance is better than Type 304 in most media. We M.B.Metal Indiais the Leading Exporter & Supplier of Nitronic 60 Round Bar. Nitronic 60 is the most effective wear and galling resistant alloy for bridge pins and other critical construction applications. We M.B.Metal Indiais the Leading Exporters & Supplier of Nitronic 60 Round Bar.

Standard:

UNS S21800 Round Bar

Alloy 218 Round Bar

AMS 5848 Round Bar

Superior corrosion resistance

Almost double the yield strength

Exceptionally low magnetic permeability

Outstanding cryogenic properties