ALLOY 201 (UNS No. N02201, DIN W.Nr. 2.4068)

M.B.Metal India. is one of the leading exporter and supplier of Nickel alloy 201 other specialty alloys for corrosion, heat resisting and other application past 10 years. We are one stop shop for nickel alloys for the requirement in pipes, plate, bars, fitting and flanges. RSEC supply material either from ex-stock or get it directly from the mill.

What makes us unique from other supplier is our capability to supply material globally in stipulated timeframe. We serve industries like aerospace, power, energy, thermal, electrical, oil & gas, marine, etc.

Nickel 201 is an alloy similar to Nickel 200 Suppliers. The Carbon content of the former is a little above that of Alloy 200. Due to this difference, Nickel 201 is preferred in caustic soda above 300 C. Nickel 201 disposes of the same high thermal and electrical conductivity and of the same magnetic and magnetostrictive properties as the grade Nickel 201.

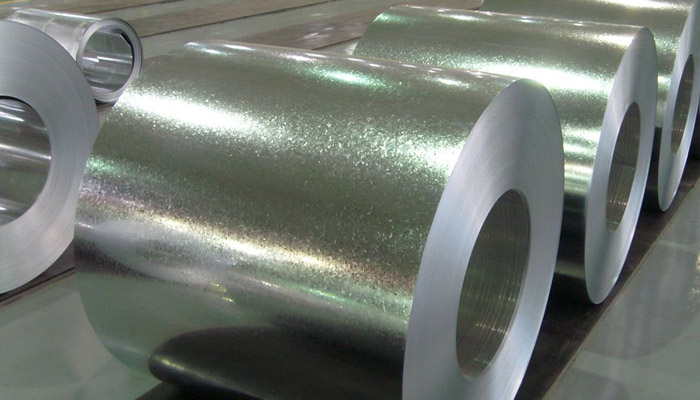

Available forms are Nickel alloy 201 Seamless Pipe,Nickel alloy 201 Welded Pipe,alloy 201 Seamless Tube, Nickel alloy 201 Welded Tube,Nickel alloy 201 Round Bars, Nickel alloy 201 Wire,Nickel alloy 201 Sheet, Nickel alloy 201 Plate,Nickel alloy 201 Forgings,Nickel alloy 201 Pipe Fittings and Nickel alloy 201 Flanges.

| Ni | Fe | Cu | C | Mn | S | Si | Other |

| 99.0 min | .40 max | .25 max | .02 max | .35 max | .01 max | .35 max |

| Product Form | Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

| Rod & Bar | Hot Finished | 60-85 | 15-45 | 55-35 | 45-80 |

| Rod & Bar | Cold Drawn/Annealed or Hot-Finished/Annealed | 55-75 | 15-30 | 55-40 | 45-70 |

| Plate | Hot-Rolled/Annealed | 55-80 | 15-40 | 60-40 | 45-75 |

| Sheet | Annealed | 55-75 | 15-30 | 55-40 | 70 max |

| Tube & Pipe | Seamless Annealed | 55-75 | 12-30 | 60-40 | 70 max |

| Seamless Pipes / Tubes | ASTM-B-161/163 |

| Welded Pipes / Tubes | ASTM-B-725/730 |

| Plates/Sheets | ASTM-B-162 |

| Bars | ATM-B-160 |

| Specific weight : | 8.89 kg/dm3 |

| Melting range : | 1435 – 1445° C |

| Welding methods : | Arc welding, TIG, MIG, autogenous welding, without thermal retreatment (detail on request) |

| Product forms : | Tubes and pipes, fittings, flanges, plates and sheet bars, forginings, wire. |

| Range of application : | Caustis evaporators, platting rods, combustion boats, chemical plant with operating temperature above 300°C, for example in caustic soda manufacturing plants. |